Flatbed wheel washer

The flatbed car washer is designed for the tires and chassis of various engineering vehicles based on the requirements of municipal administration, road administration, construction committee, environmental committee, transportation and other departments for construction vehicles. The equipment uses multi-directional high-pressure water to wash the tires and chassis parts with high pressure, so as to achieve the effect of thoroughly washing the wheels and chassis. Computer software control can automatically complete the work of washing and mud discharge. The washing water can be recycled. When working continuously, only a small amount of water needs to be added, so a lot of water resources can be saved. It is especially suitable for washing vehicles in and out of various construction sites, mining factories, cement products factories, coal mines, power plants, landfills, high-end communities and other places, so as to achieve excellent projects without dust pollution. The equipment is easy to install and transport, and can be applied to the needs of frequent transfers of various construction sites.

The flatbed car washing machine uses multi-directional high-pressure water to wash the tires and chassis, thereby achieving the effect of thoroughly cleaning the wheels and chassis. Computer software control can automatically complete the work of washing and mud discharge. The washing water can be recycled. When working continuously, only a small amount of water needs to be added, thus saving a lot of water resources.

Technical Parameters

| Item | Parameter description |

| Model | YJ220-BP |

| Dimensions | 3700mm × 3600mm × 1000mm |

| Cleaning method | Vehicles pass by themselves, automatic high-pressure spraying |

| Starting method | Automatic sensing / manual control / time control |

| Cleaning time | 30-60 seconds (adjustable) |

| Number of nozzles | More than 80 |

| Water spray pressure | 3-5 kg/cm² |

| Water pump power | 7.5kW × 2 units (high-pressure centrifugal pumps) |

| Load-bearing capacity | 100 tons |

| Water use method | Recycling |

| Sludge discharge method | Manual or automatic mud discharge |

| Power requirements | AC380V, 50Hz |

| Note: The above are conventional models, which can be customized in different sizes and load tonnages according to site requirements. | |

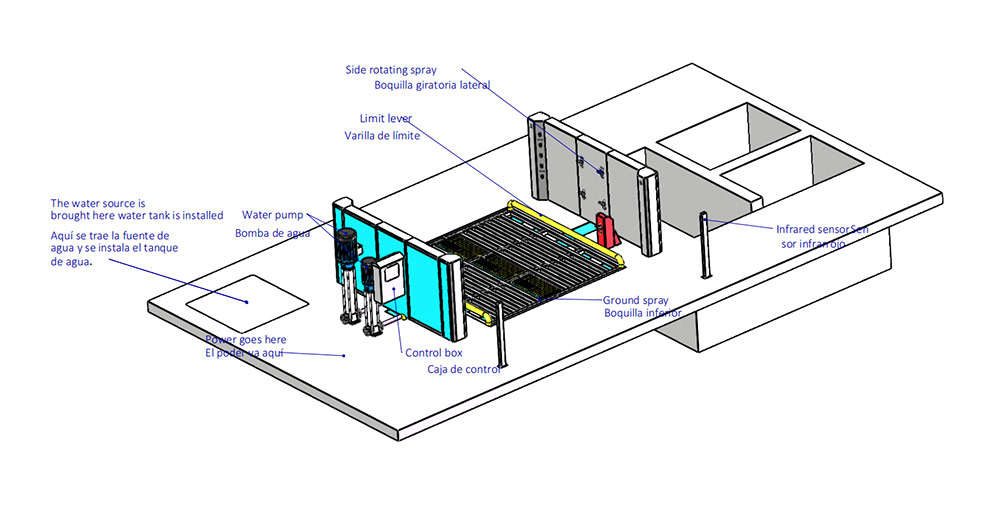

Structural composition

- Base steel structure (generally carbon steel or galvanized steel welded parts)

- Spraying system (high-pressure nozzle + water pump)

- Intelligent control system (automatic sensing or button start)

- Mud discharge circulation system (sedimentation tank + water circulation pump)

Main features

- High-pressure spraying, 360° no dead angle washing

- Vehicle automatic sensing start washing

- Water-saving circulation system, environmentally friendly and efficient

- Suitable for large and medium-sized vehicles, a variety of models are available

Application scenarios

- Construction site

- Mining factory

- Cement products factory

- Coal mine

- Power plant

- Landfill plant

- Garbage treatment plant

- Port, dock

Installation instructions

- The wheel washer installation requires foundation concrete with a thickness of ≥200mm, and reinforcement is recommended.

- The sedimentation tank needs to be designed with three-level sedimentation to facilitate return water cleaning.

- A 380V three-phase power supply with good grounding is required.

- A gate needs to be installed in the drainage ditch to prevent backflow.

- It is recommended to equip anti-freeze equipment (cold areas).

Construction layout drawing (effect drawing)